Specific industry requirements

HSM® finds the right material for your industry

Does your industry require specific grades or materials? HSM® is your certified partner with 30 years of expertise.

With us, you have a permanent partner with comprehensive carefree packages for all your needs. Spare yourself the time-consuming tasks. We’ll do them for you!

Whether it’s titanium, nickel-based alloys, high-temperature steels or other special grades – we will provide you with the required semi-finished product at short notice in accordance with your requested dimensions and form of delivery. We will also be happy to take care of any further processing. Thanks to our large network and multiflexible services, you will find the right solution for your enquiry with HSM®.

As a supplier to OEMs, Tier 1 and Tier 2 suppliers, you can trust HSM® to adhere to strict processes. We are also audited by major companies and are authorised to “restamp” products.

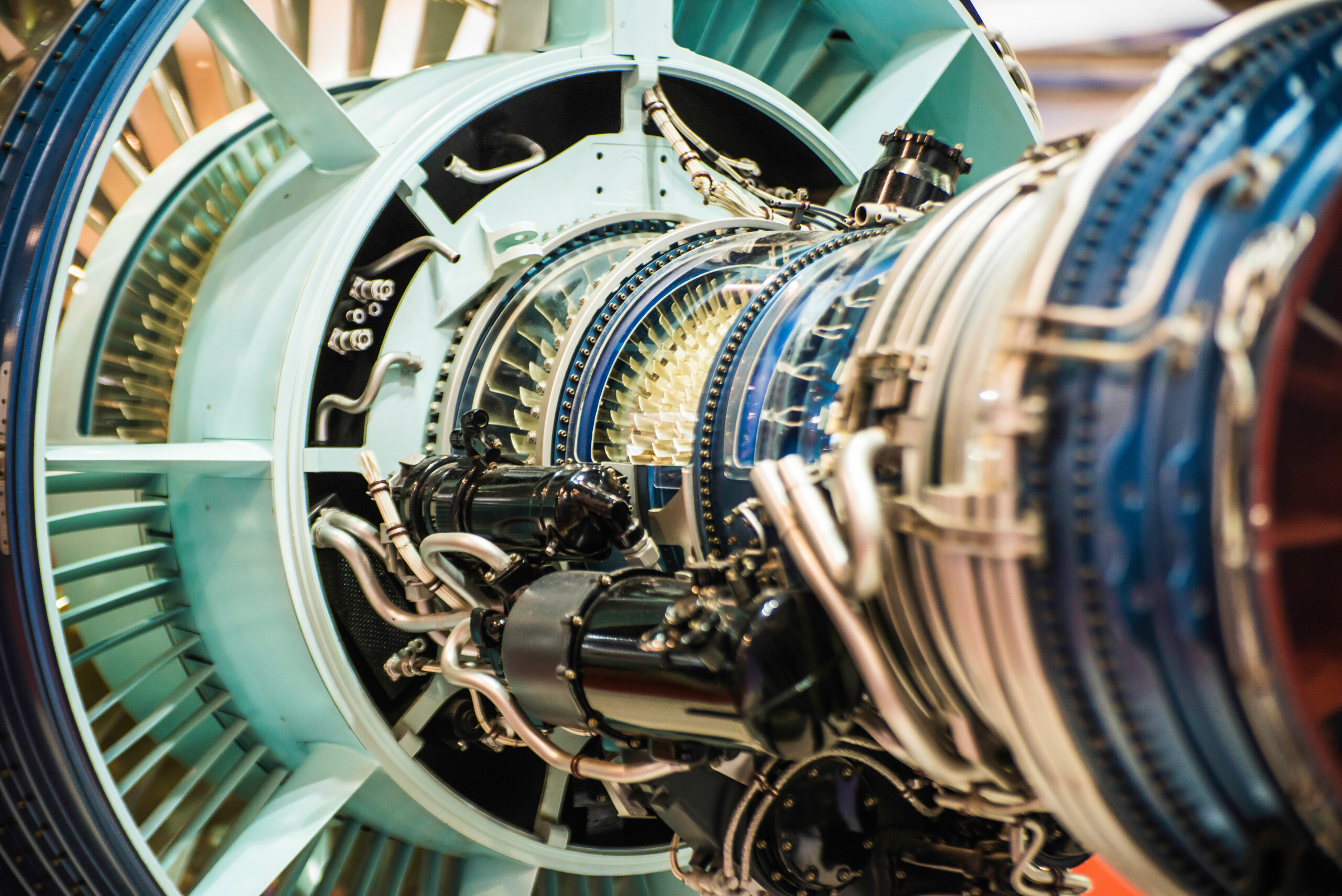

Aerospace

HSM® is your certified partner

Do you work for the aerospace industry and need material according to aerospace standards? Then HSM® is your reliable partner!

As a certified supplier to the aerospace industry, we meet the highest quality standards and ensure that our products comply with the requirements of international standards and regulations. We have been certified according to DIN EN 9120:2018 since 2016 and are a supplier to OEMs, Tier 1 and Tier 2 suppliers. With us, you can be confident that we adhere to strict processes. We are also audited by major companies and are authorised to “restamp” products.

PETER WÄLZLEIN, QUALITY MANAGEMENT HSM®

„We’re tracking every single aerospace order and monitoring the correct order processing. During the whole process we are always providing advice and support to our sales team.“

The right material for every need

At HSM® you will find a wide range of high quality metals and alloys for aerospace requirements.

Our vocation is special grades in unusual dimensions or shapes. That is why many aerospace customers trust our expertise. Depending on the dimensions and form of delivery you want, we have the semi-finished product in stock or can obtain it for you at short notice.

OUR SUPPLY RANGE INCLUDES:

You can find a detailed overview of aerospace materials in our Material Finder.

Thanks to our many years of experience and expertise, we can also provide you with professional support for individual requirements and projects.

Carefree packages with HSM®

We specialise in exceptional measurements and dimensions and will also process or custom produce your material for you. There are no limits for us – we will obtain anything that can be produced for you. Whether it’s CNC machining, laser cutting, tube machining… We take over the production and processing for you.

We place particular emphasis on fast and reliable supply so as to not interrupt your production processes. Thanks to our modern logistics network, we can also complete deliveries at short notice within no time at all.

ADVANTAGES WITH HSM®

EXTENSIVE DELIVERY PORTFOLIO

CUSTOMER-SPECIFIC STANDARDS & SPECIFICATIONS

TOOL CERTIFICATES 3.1/ 3.2 & MATERIAL TESTS

ALL POSSIBLE DIMENSIONS & DELIVERY FORMS

INCL. MANUFACTURING & MACHINING

DIGITAL ORDER PROCESSING

Energy- & environmental technology

HSM® – more efficiency in energy technology

Due to the growing effort to reduce greenhouse gas emissions, the development of new technologies for energy generation, storage and use has advanced rapidly in recent years.

The market for renewable energies such as wind power, hydropower, photovoltaics and hydrogen technology is growing steadily. However, conventional energy production from coal, natural gas and nuclear power will not decrease in the coming years, especially from a global perspective, but will continue to increase.

Our wide range of high-quality steel products meets the stringent requirements of the energy and environmental technology industry.

AREAS

of application

HYDROELECTRIC POWER PLANTS

WIND TURBINES

PHOTOVOLTAICS/SOLAR POWER PLANTS

MAINTENANCE, MODERNIZATION OR NEW CONSTRUCTION

international power plants

Hydrogen research

PETROLEUM & NATURAL GAS PRODUCTION PLANTS

OTHER ENERGY PROJECTS

REVIEW

of national power plants

As a result of certification by VGB-Powertech in accordance with standard KTA 1401 (KTA – Nuclear Safety Standards Commission), HSM® is an approved supplier for the procurement and supply of materials in accordance with KTA 1401. The KTA 1401 approval is internationally comparable with IAEA GS-R-3, NQA1 and RCC-M.

HSM® offers solutions for energy and environmental technology

Our wide range includes a variety of materials that are specially tailored to the needs of the energy and environmental technology sector. Whether it’s tubes, sheets, profiles, etc., or special alloys – you will find everything you need for your energy projects with us.

We specialise above all in special grades and unusual dimensions or shapes. We make anything that can be manufactured workable for you. We are committed to finding the individual solution for your needs. You receive everything from the raw material to the finished part custom made based on production drawings from us. Your contact takes over the whole process – we have the right solution for your requirements.

Niels Indefrey

Contact me for your

needs about energy &

environmental technology.

niels.indefrey@hsm-stahl.de

Medical & pharmaceutical technology

Precision meets high-performance materials

Are you looking for high-quality semi-finished products for the medical and pharmaceutical technology industry? Then you are exactly right with HSM®.

HSM® offers you a wide range of materials with the highest quality standards that are suitable for various applications in medical technology. Our experts are available to assist you in selecting the right raw material for your medical technology applications.

Thanks to our many years of experience as a system supplier, we specialise in exceptional dimensions and forms of delivery. There are no limits for us and we provide you with anything that can be manufactured. All enquiries are handled by us on an individual basis. You get everything you need from HSM® with our comprehensive carefree packages. We contract, coordinate and monitor all service providers for you. Spare yourself the time-consuming tasks.

SMALL MATERIAL PORTFOLIO

for medical & pharmaceutical technology

Quality stainless steel

is a popular material in medical technology due to its corrosion resistance, durability and sterilisability. It is often used for surgical instruments, implants and medical devices.

Titanium and titanium alloys

are very light, mechanically strong, corrosion resistant and biocompatible, making them ideal materials for implants. They are often used in orthopaedics, prosthetics, exoskeletons, neurosurgery and dentistry.

WILFRIED SCHÖNER

Contact me to our

services for the

medical technology.

ADVANTAGES

with HSM®

EXPERTS

In-house energy experts

QUALITY STANDARDS

Specially trained quality management

Digital ordering process

In accordance with the respective regulations

Customer-specific standards

Double attestation

Production & processing

Includes machining of the semi-finished product

Re-Stamping

Optimum traceability through re-stamping at HSM®

Form of delivery & dimensions

All feasible forms of delivery and dimensions

Cooperation with KTA-certified manufacturers

Quality assurance

Compliance with any materials test sheets

Conformity

With individual tolerances and specifications

Vehicle construction and e-mobility

High-performance materials for the automotive industry

Are you looking for an expert in high-performance materials for vehicle construction and e-mobility? Then you have come to the right place with HSM®! HSM® offers you a wide variety of high-quality materials that meet the different requirements in the automotive industry.

It is impossible to imagine our society without cars. The increasing demand for mobility and the simultaneous shortage of resources are having a significant impact on the automotive industry. Stricter requirements and legal regulations regarding environmental protection are the biggest challenges here. The focus here is on the requirements for efficiency and sustainability throughout the entire product life cycle.

The materials used must have an increasingly longer service life and improved performance while conserving natural resources. The materials must withstand ever higher temperatures, be corrosion-resistant and wear-resistant.

Our delivery program includes, among other things

Special grades in unusual dimensions or shapes are our speciality. We do not only supply you with the semi-finished product you want, we also take of processing or custom producing your material for you. That is why many vehicle construction and e-mobility customers trust our expertise. Depending on the dimensions and form of delivery you want, we have the material in stock or can obtain it for you at short notice.

You can find a selection of suitable materials for vehicle construction and e-mobility in our Material-Finder.

Our experts will be happy to assist you in selecting the right steel products for your requirements. Just ask us!

Stefanie Backhaus

Contact me.

I’ll take care of your inquiry

for the automotive industry.

We will find the right solution

for every challenge

Materials

portfolio

Production &

processing

Quality

management

Logistics &

storage solutions

Tailor-made

service